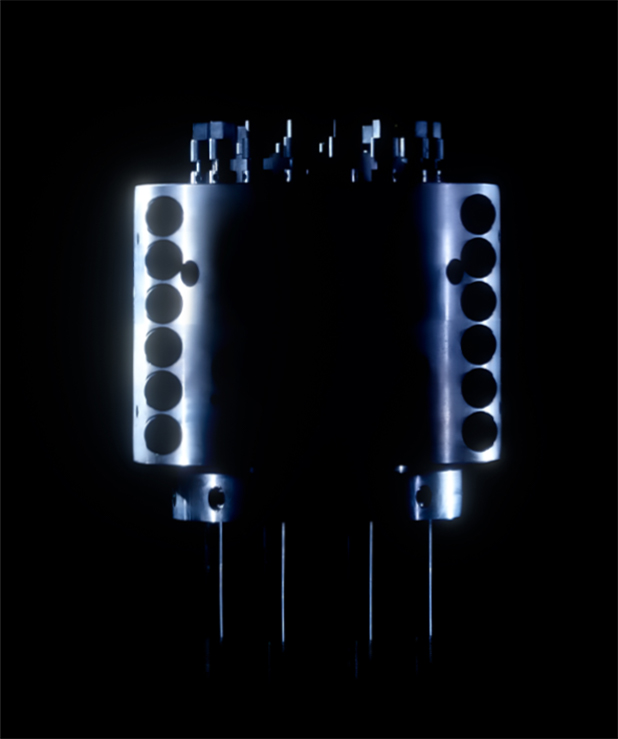

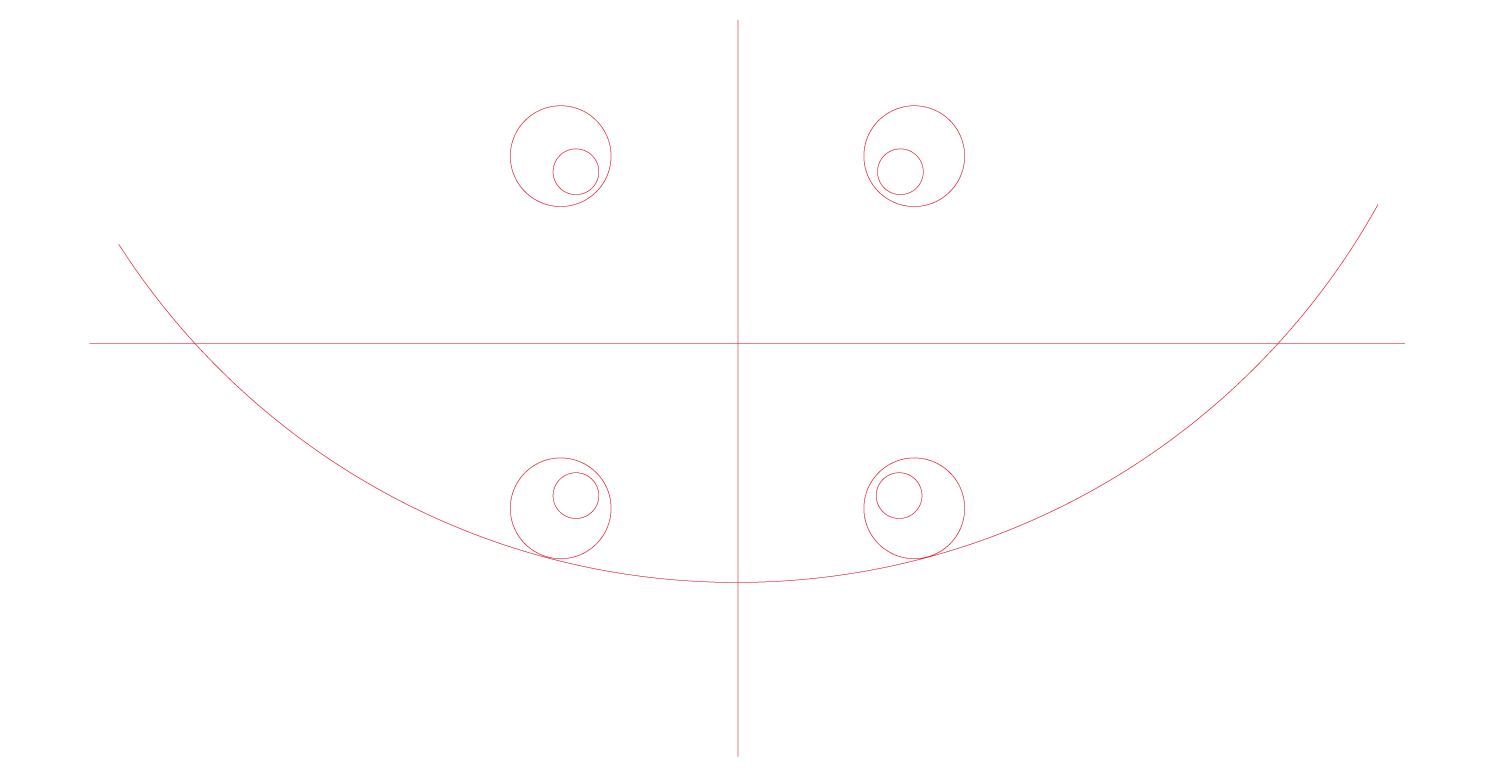

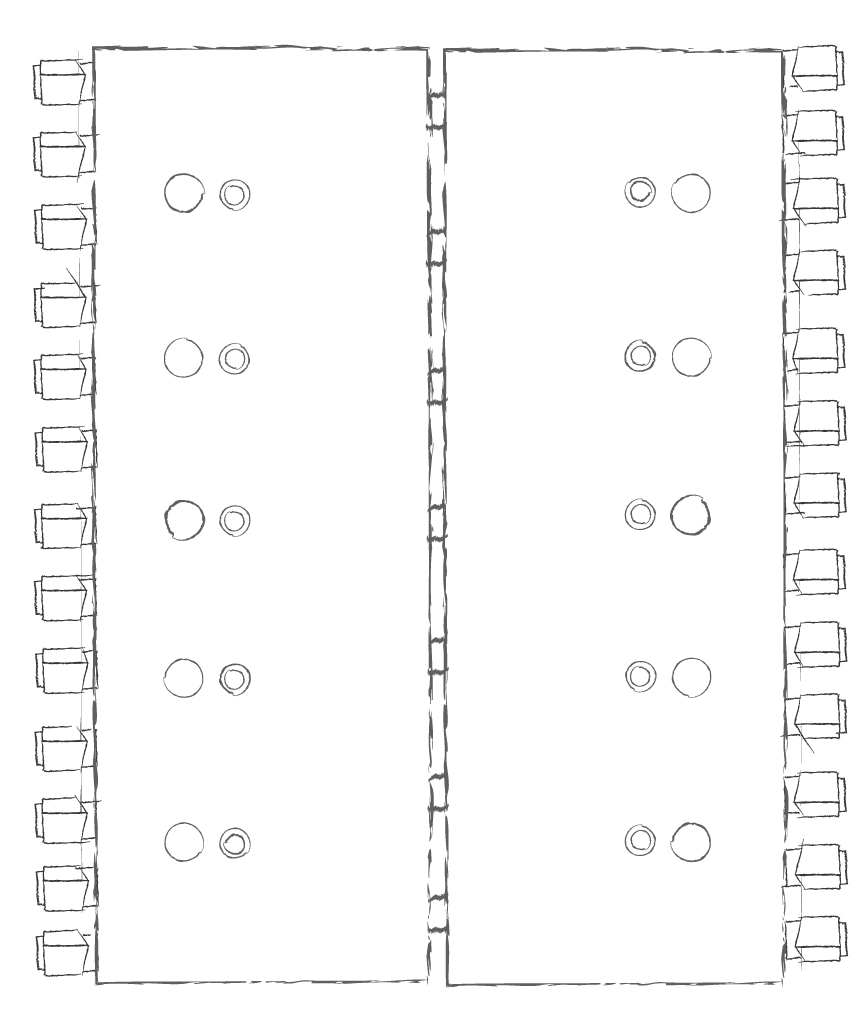

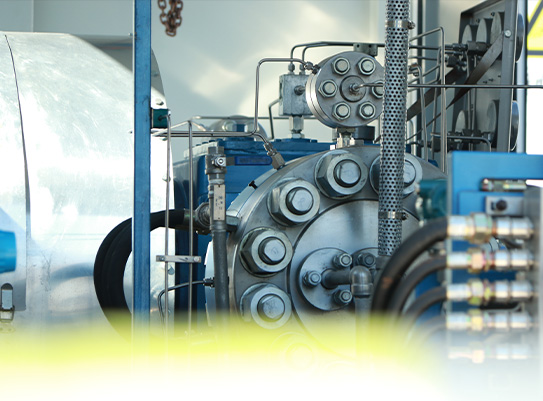

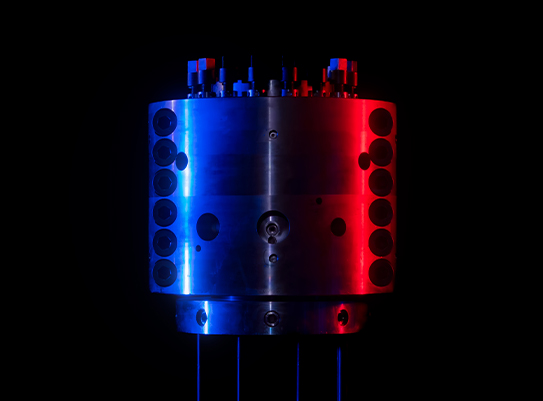

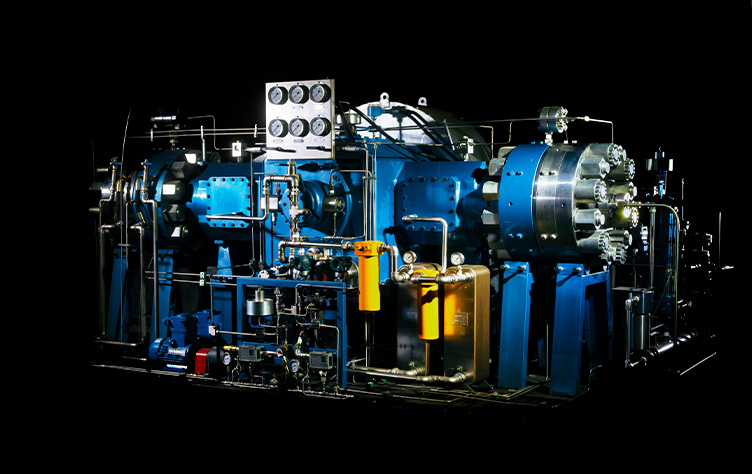

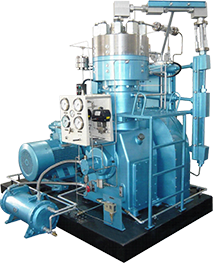

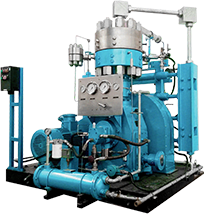

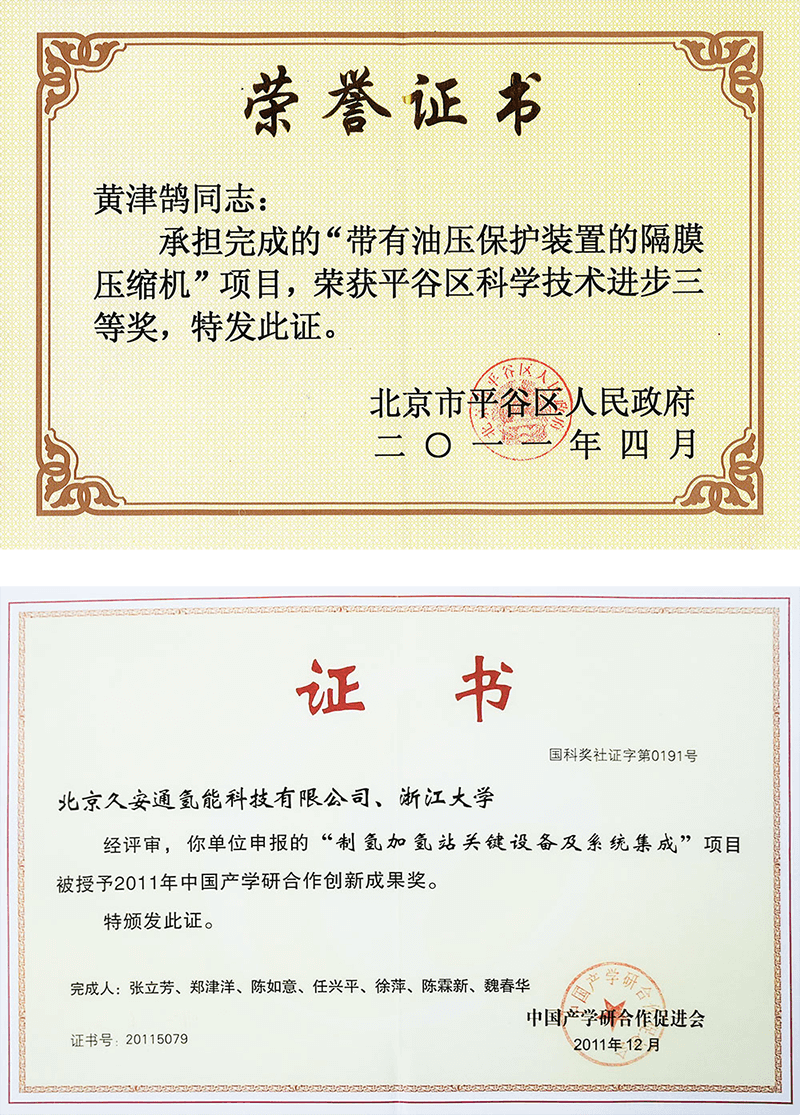

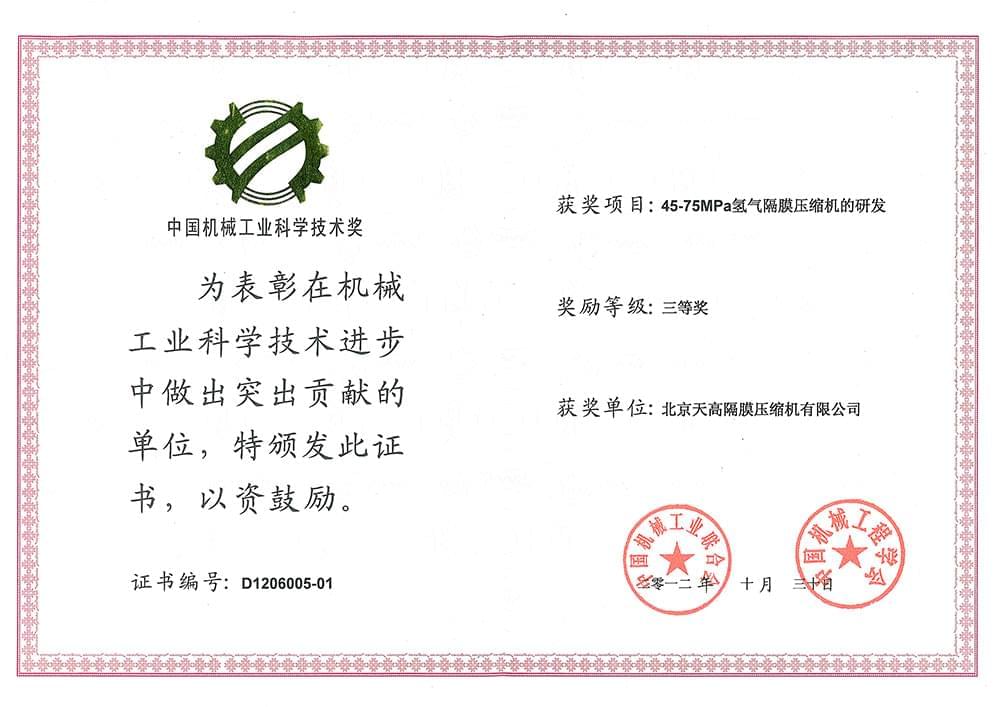

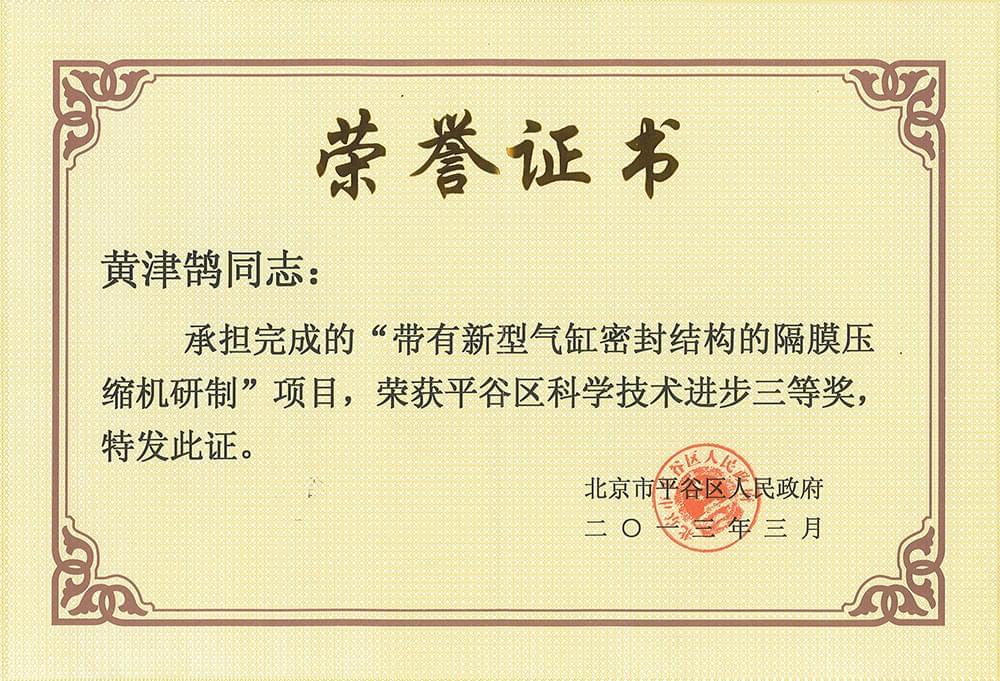

Tiangao, established in 2001, was one of the earliest domestic enterprises engaged in designing and manufacturing diaphragm compressor. Known as a technology-driven company, Tiangao holds more than 30 invention patents, utility model patents and confidential technologies, stimulating the development of China’s diaphragm compressor technology. Tiangao is making diaphragm compressors capable of up to 200 MPa discharge pressure, 75 Nm³/h single cylinder capacity, 25 tons piston force and 280 kW motor power, and has developed 26 product series with more than 1,000 product models to satisfy the ever-changing market demands.

In 2021, Huang Jinhu, Chen Ruyi and Guangdong Foran Technology Co., Ltd. jointly set up Guangdong Foran Tiangao Fluid Machinery Equipment Co., Ltd. Besides inheriting the spirit and dream of Beijing Tiangao, Foran Tiangao takes the new culture and new power injected by Foran Energy Group as its own and persists in contributing to the country and the industry.

In 2022, the upgraded modern and information-based manufacturing base was completed in Danzao Town, Nanhai District, Foshan City. At present, the production area has reached 15,000 m².

In pursuit of justice, truth and excellency, Tiangao, with high aspirations, will continue to explore, innovate and overcome, to actively undertake social responsibility, to create value for society, to provide state-of-the-art products and services that can stand the test of time on the road of long-term and sustainable development.